- Автоматизация

- Антропология

- Археология

- Архитектура

- Биология

- Ботаника

- Бухгалтерия

- Военная наука

- Генетика

- География

- Геология

- Демография

- Деревообработка

- Журналистика

- Зоология

- Изобретательство

- Информатика

- Искусство

- История

- Кинематография

- Компьютеризация

- Косметика

- Кулинария

- Культура

- Лексикология

- Лингвистика

- Литература

- Логика

- Маркетинг

- Математика

- Материаловедение

- Медицина

- Менеджмент

- Металлургия

- Метрология

- Механика

- Музыка

- Науковедение

- Образование

- Охрана Труда

- Педагогика

- Полиграфия

- Политология

- Право

- Предпринимательство

- Приборостроение

- Программирование

- Производство

- Промышленность

- Психология

- Радиосвязь

- Религия

- Риторика

- Социология

- Спорт

- Стандартизация

- Статистика

- Строительство

- Технологии

- Торговля

- Транспорт

- Фармакология

- Физика

- Физиология

- Философия

- Финансы

- Химия

- Хозяйство

- Черчение

- Экология

- Экономика

- Электроника

- Электротехника

- Энергетика

Methods of Research

In order to do laboratory research to determine physical and chemical features of production of complex fertilizer, containing phosphorus and nitrogen, the selection of phosphorus sludge has been taken carried out from different levels sludge collectors of LLP «Kainar» (Shymkent city). The cottrell dust is taken from collectors of cottrellmilk of Novo-Zhambylskyi phosphorus factory (Taraz city). These selected samples were dried out at the temperature of 60-80°С and screened through a shaking sieve in accordance with State Standard (GOST) 21560-82 «Mineral fertilizers». Granulometric composition was determined using the shaking sieve screen «Analizette 3». Substantial composition of phosphorus sludge and cottrell dust were determined by chemical method according to GOSTs [8]. Mineralogical composition and microstructure of samples of phosphorus sludge and cottrell dust have been studied using Scanning Electronic Microscopy SEM JEOL of brand JSM6490 LV. It is worth to notice, that chemical and roentgen – diffractometric analyses of samples of technogenicwastes in LLP «Kazphosphat» have been carried out repeatedly. In these experimental conditions the mixture of phosphorus sludge and cottrell dust, taken in mass ratio 2: 1, was subjected to decomposition in acid environment, formed from water solution of ammonia sulphate and humic acid. Duration of the decomposition process was 60 minutes at the temperature of 60°С.

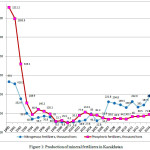

Statistics of Production and of Mineral Fertilizer Consumption

Elimination of negative impacts of natural risks, preservation of soil fertility, cropping capacity of agricultural crops to a large extent depends on usage of mineral fertilizers. Taking into account this fact Kazakhstan has adopted measures that stimulate the agricultural sector; also state support for expansion of fields of prior agricultural crops, growth of their productivity and improvement of their seed grain is provided for. The program «Agrobusiness -2020» is being carried out at present, growth of export potential of agricultural sector to countries of Eurasian Economic Union (EEU) was the result of this program. With that mineral fertilizers are introduced only on 5% of cultivated areas (3 kg per hectare). In Russia about 38 kg per 1 hectare of cultivated land are used, whereas in Europe and the USA the analogous figure is 130-140 kg. Low level of using mineral fertilizers is connected with the fact, that in spite of state subsidization of this branch, peasant farms and farm enterprises cannot buy them in full. The thing is, that initially the subsidization program was planned irrationally. The agrarian can get 50% of subsidies for local and 30% for import fertilizers only after the purchase of necessary products. There are also many complications and bureaucratic longstops in getting subsidies. Poor competitiveness of produced fertilizers, their high transportation costs make the agricultural complex products not competitive.

At sufficiency of mineral resources the production of fertilizers is characterized by a poor level of development. At present in Kazakhstan only two factories operate, they are: LLP «Kazphosphat» (Taraz city) and «KazAzot» (Aktau city). The volume of nitrogenous fertilizer consumption in the internal market is estimated as 329 thousand tons per year. In 2014 import of this production to Kazakhstan was 166 thousand tons, i. e. half of the country’s demand. Level of ammonium saltpeter consumption in Kazakhstan is $50/ hectare, whereas in neighboring Russia it is $150/hectare, in Germany it is about $200/hectare.

It is foreseen to increase capacities of production of ammonia andnitrogen fertilizers up to 400 thousand tons per year by 2018. More than $160 million will be invested. Modernization of LLP «KazAzot» will allow to increase the production competitiveness, because the production cost of nitrate fertilizer will decrease by 35 per cent- $140 per ton, labor productivity will grow four times - $45 thousand. 40% of fertilizers are supposed to be exported, including the deliveries into the EEU countries. Factory of mineral fertilizers LLP “Kazphosphat” produces a wide range of phosphatic fertilizers [16]:

ammophos (mixture di-, monoammonium phosphate) – 46% Р2О5, , 10% N;

ordinary superphosphate – 19% Р2О5;

sulfoammophos – 18% Р2О5, 18% N;

nitroammophos - 22% Р2О5, 22% N;

feed tricalcium phosphate – 27% P2O5;

feed calcium-natriumphosphate - 41% P2O5.

The output is realized in China, Ukraine, Belarus, Tadjikistan. A large work in development of phosphoric fertilizers market of Afghanistan, Kyrgyzstan, Romania, Czechia, Bulgaria, Iran is being carried out. Construction of a new plant for production of phosphorus, nitrogenious and complex fertilizers has started in Kazakhstan. This factory with capacity of about 1 million tons per year will be based on the deposit Kok-ZhoninZhambyl oblast. It will provide 100% of Kazakhstan internal market. Surplus of products is intended for export. Capacity of the factory is much greater, than the demand of Kazakhstan market. In 2018 it is expected that the factory will function at its full production capacity. The planned investments are approximately 2 billion dollars.

Construction of a factory of potash fertilizers will be started in Aktobe oblast. China invests 3, 8 billion dollars in this project. Chinese companies have offered to increase the production from one million tons up to seven million tons per year in 2025 taking into account the export of surpluses. It should be noted, that practically all the countries export part of manufactured mineral fertilizers: phosphorus ones – 35-50% of the world production, potassium – 80%, nitrogen – 25-40%. In 2014 about 47 million tons of fertilizers were produced in the world, in terms of 100% of nutrients. Today the first-rate producers of mineral fertilizers are: China, which controls 21% of the market, the USA (13%), India (10%), Russia (8%) and Canada (8%). In west Europe 80% of total production of fertilizers are controlled by 8 large companies, in the USA 60% of nitrogenous fertilizers are provided by 5 companies. The last years the influence of the USA in the world market of fertilizers goes down. Since 2006 high rates of growth are presented by the markets of South East Asia and Latin America.

In Kazakhstan production of mineral fertilizers does not In Kazakhstan the production of mineral fertilizers does not have a clear dynamics of growth. Before collapse of the USSR this sector of production worked for internal consumption, later it stopped to be demanded inside the country, volumes of consumption of fertilizes decreased several tens of times. Therefore, the sector was forced to reorient for export. Some increase of volumes was reached in producing ammonia, nitrogenous fertilizers after 2007; however, the capacities were not restored. The last years the volumes of fertilizers’ export are approximately 220-250 thousand tons. Import of fertilizers in Kazakhstan in 2014 was 246. 8 thousand tons at the sum of 84161 thousand dollars. The exported fertilizers are: ammonium, sodium tripolyphosphate, other fertilizers, containing two nutrients – nitrogenand phosphorus. Imported goods are: herbicides, phytohormones, chemical remedies for plant protection. 98% of imported phosphorus fertilizers are brought from Uzbekistan. Agricultural formations of various patterns of ownership (in Kazakhstan there are more than 200 thousand formations) cry out for complex fertilizers, containing nitrogen, phosphorus and potassium because of the dry climate and soil low fertility. The most demanded are: ammophos, which is a concentrated ballastless fertilizer with two nutrients in soluble form – nitrogen and phosphorus. The situation of phosphorus in farming in Kazakhstan is quite vital. Therefore, we would like to concentrate on conditions of manufacturing more effective phosphorus fertilizers.

| Production of mineral fertilizers in Kazakhstan |

Discussion of the Research Results

The widely demanded complex NP fertilizer: ammophos is characterized by content of the main component – monoammonium phosphate NH4H2PO4 with admixture (up to 10%) of diammonium phosphate (NH4)2HPO4. Production of ammosphos according to traditional technology anticipates decomposition of phosphates in conditions of wet-process phosphoric acid abundance. From then on ammoniation by acidic phosphate suspension, its further boiling-down, granulating and dehydration of boiled down mass take place.

Unlike the traditional method we used for production of ammophos the mixture of phosphorus sludge, cottrell dust, ammonia sulphate and humic acid at their various ratios. At this ammonia sulphate was used to increase nitrogenous component in the composition of produced ammophos; the humic acid with рН = 0. 760 was used as a substitute of sulphuric, nitric or phosphoric acids. Phosphorous sludge was selected from different levels of sludge collectors of LLP «Kainar», and cottrelldust was taken from the collectors of Novo-Dzhambyl phosphorus factory. It is found, that the substantial composition of phosphorus sludge and cottrelldust correspond to the following content:

in the composition of phosphorus sludge, %: P2O5 total – 17. 01, K2O – 6. 72, Na2O – 0. 41, SiO2 – 45. 38, CaO – 13. 74, MgO – 4. 16, Al2O3 – 1. 08, Fe2O3 – 0. 81, C – 5. 91, S – 0. 40;

in the composition of cottrelldust, %: P2O5 total. – 23. 05, K2O – 7. 05, Na2O – 0. 55, SiO2 -25. 08, CaO – 8. 99, MgO -1. 29, Al2O3 – 2. 66, С – 22. 34, S – 0. 36.

The results, obtained on SEM, showed, that minerals – calcium silicates, diopside and potassium aluminum silicates with inclusion of phosphate compounds of calcium prevail in phosphorus sludge andcottrell dust [22]. Chemical aspect of the decomposition process of the mixture of phosphorus sludge and cottrell dust in acid environment of water mixture of ammonia sulphate and monohydric humic acid can be described by the following equation:

Ca5(PO4)3F + 8humic acid + 2(NH4) 2SO4 = = 2CaSO4 + 4NH4(humate) + H3PO4 + 2Са(humate)2 + Ca(H2PO4)2 + HF (1)

After decomposition the mixture was subjected to filtration. It has been found that the obtained liquid phase – the filtrate has density of 1. 08 and рН = 3. 5. This gives evidence, that the filtrate is a phosphoric acid with the concentration of 14. 60%. The derived phosphoric acid was ammoniated by 25% gas-liquor up to рН=6. 0. The process of neutralization of phosphoric acid by gas-liquor can be described by known reactions of the following types:

H3PO4 (liquid) + NH4ОН (liquid) = NH4H2PO4 (crystal) + Н2О (2)

H3PO4 (liquid) + 2NH4ОН (liquid) = (NH4)2HPO4 (crystal) + 2Н2О (3)

The process of ammonization of filtrate phosphoric acid by gas-liquor was carried out till reaching the final рН=6. 0. The derived neutralized solution was subjected to drying in the drying cabinet at temperature 105°С up to complete crystallization of the mixture of monoammonium phosphate and diammonium phosphate. As the result of drying white powder with high solvability in water was derived. The derived product is being analyzed for content of assimilable and water-soluble Р2О5, ammonia and nitrogen. The accepted ratio of phosphorus sludge to cottrell dust, the temperature mode of the process of their decomposition in acid environment, expendable indices of 30% solution of ammonia sulphate and humic acid are presented in table 1. The conditions of carrying out the process of ammoniation and the characteristic of the final product are also presented here. Analysis of the results of table 1 shows, that the largest indices onassimilableР2О5 and water-soluble Р2О5 at maximum amount of nitrogen in the final product can be observed in experiment 4. Thereat, as it seen in figure 2, the maximum amount of assimilable Р2О5 and water-soluble Р2О5 and nitrogen in the final product is observed at specific discharge of 0. 20 liter of humic acid per one kilogram of the mixture of phosphorus sludge and cottrell dust.

Element-by-element composition of complex mineral fertilizer

| Element | N | O | Na | Mg | P | S | Cl | K | Ca | Mn | Zn |

| Weightcomposition, % | 11. 68 | 48. 81 | 1. 92 | 1. 60 | 23. 38 | 0. 61 | 3. 84 | 5. 84 | 1. 84 | 0. 18 | 0. 27 |

| Weight composition, in terms of oxides, % | 11. 68 | - | 2. 59 | 2. 65 | 53. 56 | 1. 31 | - | 7. 03 | 2. 57 | 0. 23 | 0. 33 |

From figure 3 it follows, that the surface of the decomposed micro section is characterized by high ability to pass light. The results of element-by-element and weight analyses of complex mineral fertilizer tell about the advantage of reality of processes’ behavior of ammophos production according to the developed methods. As it is follows from P2O5 compoundsin complex with nitro compounds are the main constitutive minerals of the manufactured product. Also K2O (up to 7. 03%), NaNO3 (up to 2. 59%) and admixtures of magnesium sulfate and calcium within limits of 2. 57-2. 65% are present as impurity inclusions. The manufactured product according to the content of phosphoric anhydride (53. 56%) and nitrogen (11. 68%) corresponds to ammophos GOST 18918-85 of grade А with zinc admixtures [8]. The analysis of data of table 3 and figure 4 about element-by-element composition of dry residue, obtained after filtration, proves the presence of carbon in it – 12. 73%, of silicon -16. 18% (in terms of SiO2 -34. 60%), of fluorine – 5. 30%, of calcium – 8. 73% (in terms of СаО – 12. 21%) and phosphorus – 5. 81% (in terms of P2O5 – 13. 31%).

Element-by-element composition of dry residue, derived after filtration

| Element | C | O | F | Na | Mg | Al | Si | P | S | Cl | K | Ca | Mn | Fe | Zn |

| Weightcomposition, % | 12. 73 | 39. 7 | 5. 3 | 0. 4 | 1. 2 | 1. 3 | 16. 2 | 5. 8 | 0. 9 | 0. 2 | 2. 8 | 8. 7 | 0. 1 | 0. 5 | 0. 3 |

| Weight composition, in terms of oxides, % | 12. 73 | - | 5. 3 | 0. 6 | 2. 0 | 2. 4 | 34. 6 | 13. 3 | 2. 2 | - | 3. 3 | 12. 2 | 0. 1 | 0. 8 | 0. 4 |

Results of chemical analysis of dry residue (table 4) proves the presence of Р2О5 assimilable -13. 25%, Р2О5 water-soluble– 4. 75% and N – 4. 75%, and also humic acid 7-10% in it. The above mentioned information allows us to view the possibility of using dry residue as ammoniated superphosphate. It is found, that this product is characterized by high solubility in water. So for example, its granules 5-8 mm in diameter dissolve in water within 3-5 seconds. Successful experiments allow to design the technology of production of the desirable product, meant for complete using sludge, cottrell dust and involvement of wastes.

Experiments show, that the problem of wastes is in imperfect technology, which causes them: mountains of phosphorus sludge, non-commercial ores, soil salinization, environmental contamination. The technology of utilization of phosphorus sludge and cottrell dust, offered by us, decreases harmful environmental impact. According to our calculations the production costs of a new fertilizer are much less than, than those ones according to the current scheme of ammophos production by about 19% [16]. This has a big significance, when expensiveness of fertilizers does not allow the farm companies to buy them in sufficient amount. This leads to a significant drop of crops capacity. Approximate costs are being planned in the following amount (table 5). The developed way of new fertilizer production by means of wastes’ utilization is recommended for introduction into the production process on the existing area of ammophos shop of the factory «Mineral fertilizers» of LLP «Kazphosphat».

|

|

|

© helpiks.su При использовании или копировании материалов прямая ссылка на сайт обязательна.

|