- Автоматизация

- Антропология

- Археология

- Архитектура

- Биология

- Ботаника

- Бухгалтерия

- Военная наука

- Генетика

- География

- Геология

- Демография

- Деревообработка

- Журналистика

- Зоология

- Изобретательство

- Информатика

- Искусство

- История

- Кинематография

- Компьютеризация

- Косметика

- Кулинария

- Культура

- Лексикология

- Лингвистика

- Литература

- Логика

- Маркетинг

- Математика

- Материаловедение

- Медицина

- Менеджмент

- Металлургия

- Метрология

- Механика

- Музыка

- Науковедение

- Образование

- Охрана Труда

- Педагогика

- Полиграфия

- Политология

- Право

- Предпринимательство

- Приборостроение

- Программирование

- Производство

- Промышленность

- Психология

- Радиосвязь

- Религия

- Риторика

- Социология

- Спорт

- Стандартизация

- Статистика

- Строительство

- Технологии

- Торговля

- Транспорт

- Фармакология

- Физика

- Физиология

- Философия

- Финансы

- Химия

- Хозяйство

- Черчение

- Экология

- Экономика

- Электроника

- Электротехника

- Энергетика

Results and discussion

4. Results and discussion

Comparison of results of thermodynamics design with the results of experimental research testifies to their quality coincidence and in too time allows to suppose that in experiments on liquid-phase renewal the process was conducted not to the end. The some understated exit of metallic phase testifies in behalf on the last supposition, overpriced maintenance of iron in the metal and accordingly more subzero, than suppose design results, maintenance in the metal of other elements (in particular chrome). It is possible to suppose that the increase of time of renewal will influence on the increase of exit of metal and degree of his apartness in relation to the bulk of slag.

The obtained experimental data specify on subzero efficiency of the use of unmagnetic faction of slag in the process of liquid-phase renewal. Maybe, preliminary realization of additional operations on dividing of initial unmagnetic constituent into the gob and metal-containing components assisted the increase of such efficiency.

Theoretical and experimental studies allow us to draw the following conclusions:

1) Mass of the metallic phase got as the result of renewal can make to the 20 t masses of original slag and even some higher. The iron contained in the slag can be recovered practically fully. Prevailing or noticeable part of such elements, as chrome, nickel, manganese, and also some other valuable components can go across in the complement of metal.

2) Liquid-phase renewal of slag needs to be conducted at temperatures about 1500 °C and higher with the purpose of more complete renewal of metals and formation of the consolidated metallic phase. Useful foods of process the liquid metal and impoverished on heavy metals oxide fusion, consisting of oxides of calcium, silicon, magnesium and aluminium that can be used in the production of cement, will become at this temperature. Combination of process of processing of slag with a cement production will allow largely to cover the cost the power expenses of the examined process.

3) To formation of the consolidated metallic phase (to the association of drops of the recovered metal) the increase of stake will promote a metallic constituent in the volume of stove with the height of temperature. The ratio between the oxides and metal can be improved due to introduction to reactionary mass of kinglets of metal, being in composition dump slags and extracted from them in the process of preparation to renewal.

4) Preliminary solid-phase renewal of slag is conducted at temperatures about 1100-1200 °C with the purpose of minimization charges of energy. This process will allow to translate greater part of iron being in the slag in form oxides, in a form receptive to the magnetic separation. The subsequent magnetic separation will allow to separate faction with enhanceable maintenance of valuable metals, that will be sent to the liquid-phase processing from the oxide faction that can be used for the production of building materials impoverished on valuable metals. The use during liquid-phase renewal of the only enriched faction will allow substantially to improve the betweenness by the amounts of oxide and metallic constituent in the volume of stove.

5) Use of repairer (carbon) mass about the 10 t masses of refurbishable slag it must be enough for realization of procedure. Measures on utilization of large volumes of carbon monoxide and steams of metals it is necessary to provide for at planning of aggregates for realization of the developed technology. Using of appearing gas as the repairer for preliminary solid-phase renewal of slag can become one of ways of utilization CO. The preliminary results of thermodynamics design testify in behalf on such possibility. Such approach will allow to get the substantial economy of hard repairer (to prevent it irretrievable losses with unmagnetic part of slag), and also to use the heat of gas mixture, got in the process of liquid-phase renewal, for heating of the slag exposed to solid-phase renewal. Carbon monoxide can be used and as the fuel for heating of refurbishable slag.

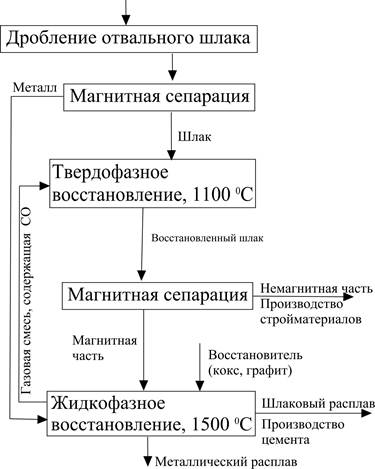

The analysis of results allows to recommend the chart of processing of dump slags of steel-smelting production, shown on the picture 11.

Figure 11 - Chart of processing of steel-smelting dump slags

|

|

|

© helpiks.su При использовании или копировании материалов прямая ссылка на сайт обязательна.

|