- Автоматизация

- Антропология

- Археология

- Архитектура

- Биология

- Ботаника

- Бухгалтерия

- Военная наука

- Генетика

- География

- Геология

- Демография

- Деревообработка

- Журналистика

- Зоология

- Изобретательство

- Информатика

- Искусство

- История

- Кинематография

- Компьютеризация

- Косметика

- Кулинария

- Культура

- Лексикология

- Лингвистика

- Литература

- Логика

- Маркетинг

- Математика

- Материаловедение

- Медицина

- Менеджмент

- Металлургия

- Метрология

- Механика

- Музыка

- Науковедение

- Образование

- Охрана Труда

- Педагогика

- Полиграфия

- Политология

- Право

- Предпринимательство

- Приборостроение

- Программирование

- Производство

- Промышленность

- Психология

- Радиосвязь

- Религия

- Риторика

- Социология

- Спорт

- Стандартизация

- Статистика

- Строительство

- Технологии

- Торговля

- Транспорт

- Фармакология

- Физика

- Физиология

- Философия

- Финансы

- Химия

- Хозяйство

- Черчение

- Экология

- Экономика

- Электроника

- Электротехника

- Энергетика

X600 High Temperature Pleated Elements

X600 High Temperature Pleated Elements

Features

• Failure free sealing concept

• No bag-house modification necessary

• Increased productivity and efficiency

• Longer service life

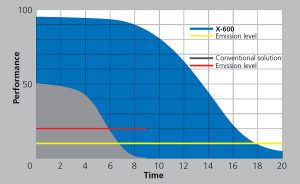

• Reduced energy consumption and emission levels

Applications

The X-600 is a unique, patented, pleated filter used in finishing of titanium dioxide pigment and other applications.

The new pleated cartridges resist high temperatures and have almost three times the surface area of other filter bags of the same diameter. In addition to providing increased air flow and superior efficiency, the pleated cartridges can replace old filters with no system modifications required. It surpasses the performance of any regular bags on the market and can increase service life by more than 100%. Outstanding results of 54 months have been shown for product lifetime. This represents the longest lifetime for any micronizer bag house lifetime in the world.

1. 100% Metal top and end caps

2. Ultra-resistant aluminium sealing

3. Sealed stitching

4. Galvanised steel core

5. E-PTFE membrane

6. Fibreglass felt with type a phenolic resin

7. Heavy duty stainless steel bands

Benefits- Reduced operational cost

Existing conventional filtration solutions can be replaced by Sefar’s X-600 High temperature pleated elements without any modification of the bag house – an inestimable added value. The process profits from the reduction of the differential pressure as energy consumption of fans and use of compressed air for cleaning systems are lowered remarkably.

Longer service life and operational reliability of the X-600 – High temperature pleated element minimise replacements and therefore shut-downs which has a positive effect on operational cost.

Superior design for extended service life

Sefar’s patented innovative potting compound makes sealing of end caps almost unbreakable. X-600 – High temperature pleated elements can be operated continuously at temperatures as high as 260°C without any degradation of the potting compound, being usually the main reason for element destruction. The X-600 – High temperature pleated elements are also shorter than conventional elements protecting them from abrasion at the inlet zone.

|

|

|

© helpiks.su При использовании или копировании материалов прямая ссылка на сайт обязательна.

|