- Автоматизация

- Антропология

- Археология

- Архитектура

- Биология

- Ботаника

- Бухгалтерия

- Военная наука

- Генетика

- География

- Геология

- Демография

- Деревообработка

- Журналистика

- Зоология

- Изобретательство

- Информатика

- Искусство

- История

- Кинематография

- Компьютеризация

- Косметика

- Кулинария

- Культура

- Лексикология

- Лингвистика

- Литература

- Логика

- Маркетинг

- Математика

- Материаловедение

- Медицина

- Менеджмент

- Металлургия

- Метрология

- Механика

- Музыка

- Науковедение

- Образование

- Охрана Труда

- Педагогика

- Полиграфия

- Политология

- Право

- Предпринимательство

- Приборостроение

- Программирование

- Производство

- Промышленность

- Психология

- Радиосвязь

- Религия

- Риторика

- Социология

- Спорт

- Стандартизация

- Статистика

- Строительство

- Технологии

- Торговля

- Транспорт

- Фармакология

- Физика

- Физиология

- Философия

- Финансы

- Химия

- Хозяйство

- Черчение

- Экология

- Экономика

- Электроника

- Электротехника

- Энергетика

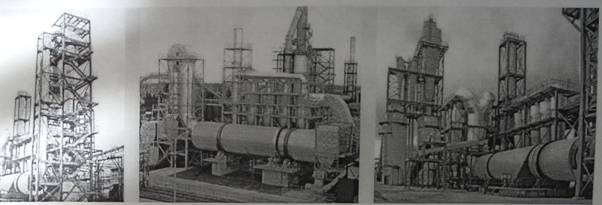

TT/TT-LL Drum Dryer. Application. Description. Customer. benefits. Technical. features

TT/TT-LL Drum Dryer

Application

Drying of wood particles, OSB strands, wafers, sawdust, bark, disintegrated seasonal annual crops and biomass

Description

Wet material is fed via a rotary valve into the rotating drum. Heat is transferred mainly through convection into the material. Drum Dryer TT-LL separates the dried material with cyclones from the air stream. On the upgraded model TT the drum releases most of the dried material by gravity through a discharge box. In the gas stream suspended fine particles are conveyed to the cyclone battery.

Customer

benefits

- High capacity

- Large temperature gradient

- Low fire risk due to low dryer outlettemperature

- High standard of operating safety and reliability

- Low specific energy requirement

- Internals designed according to material characteristics

Technical

features

Explosion protection system conforms to ATEX regulations

Utilizes recirculation air to reduce exhaust air volume

TT with discharge box for gentle discharge of the material or of heavy material particles Optional: integrated or separate predryer with heavy particle separation and second infeed for reject material from production

Energy sources:

Direct heating, flue gases from

- Gas, dust, light and/or heavy oil burner

- Energy system (e. g. grate firing systems)

- Turbine exhaust gas

- Combination of heating systems mentioned above Indirect heating

- Heat exchangers with steam or thermal oil for special application

|

|

|

© helpiks.su При использовании или копировании материалов прямая ссылка на сайт обязательна.

|