- Автоматизация

- Антропология

- Археология

- Архитектура

- Биология

- Ботаника

- Бухгалтерия

- Военная наука

- Генетика

- География

- Геология

- Демография

- Деревообработка

- Журналистика

- Зоология

- Изобретательство

- Информатика

- Искусство

- История

- Кинематография

- Компьютеризация

- Косметика

- Кулинария

- Культура

- Лексикология

- Лингвистика

- Литература

- Логика

- Маркетинг

- Математика

- Материаловедение

- Медицина

- Менеджмент

- Металлургия

- Метрология

- Механика

- Музыка

- Науковедение

- Образование

- Охрана Труда

- Педагогика

- Полиграфия

- Политология

- Право

- Предпринимательство

- Приборостроение

- Программирование

- Производство

- Промышленность

- Психология

- Радиосвязь

- Религия

- Риторика

- Социология

- Спорт

- Стандартизация

- Статистика

- Строительство

- Технологии

- Торговля

- Транспорт

- Фармакология

- Физика

- Физиология

- Философия

- Финансы

- Химия

- Хозяйство

- Черчение

- Экология

- Экономика

- Электроника

- Электротехника

- Энергетика

Normalizing. Carburization. Surface Hardening

Normalizing

Normalizing involves heating steel, and then keeping it at that temperature for a period of time, and then cooling it in air. The resulting microstructure is a mixture of ferrite and cementite which has a higher strength and hardness, but lower ductility. Normalizing is performed on structures and structural components that will be subjected to machining, because it improves the machinability of carbon steels.

Carburization

Carburization is a heat treatment process in which steel or iron is heated to a temperature, below the melting point, in the presence of a liquid, solid, or gaseous material which decomposes so as to release carbon when heated to the temperature used.

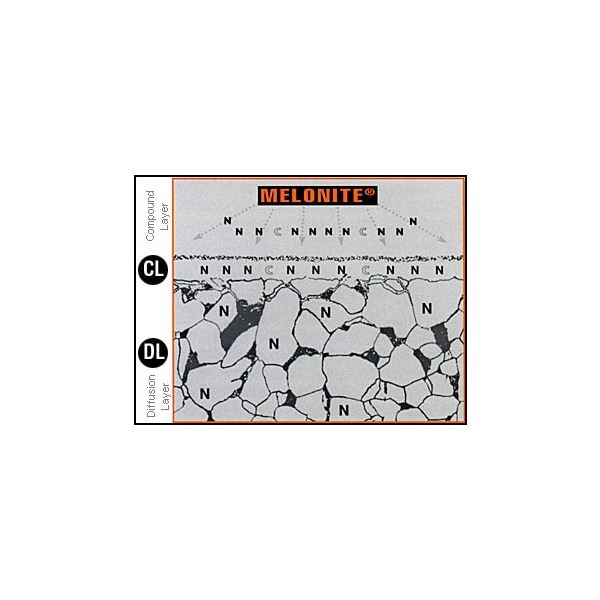

Melonite formation by heat treatment of steels

Melonite formation by heat treatment of steels

The outer case or surface will have higher carbon content than the primary material. When the steel or iron is rapidly cooled by quenching, the higher carbon content on the outer surface becomes hard, while the core remains tough and soft.

Surface Hardening

In many engineering applications, it is necessary to have the surface of the component hard enough to resist wear and erosion, while maintaining ductility and toughness, to withstand impact and shock loading. This is known as surface hardening. This can be achieved by local austentitizing and quenching, and diffusion of hardening elements like carbon or nitrogen into the surface. Processes involved for this purpose are known as flame hardening, induction hardening, nitriding and carbonitriding.

|

|

|

© helpiks.su При использовании или копировании материалов прямая ссылка на сайт обязательна.

|